3D Trends 2025: Shaping the Future of Technology and Beyond

Related Articles: 3D Trends 2025: Shaping the Future of Technology and Beyond

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to 3D Trends 2025: Shaping the Future of Technology and Beyond. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

3D Trends 2025: Shaping the Future of Technology and Beyond

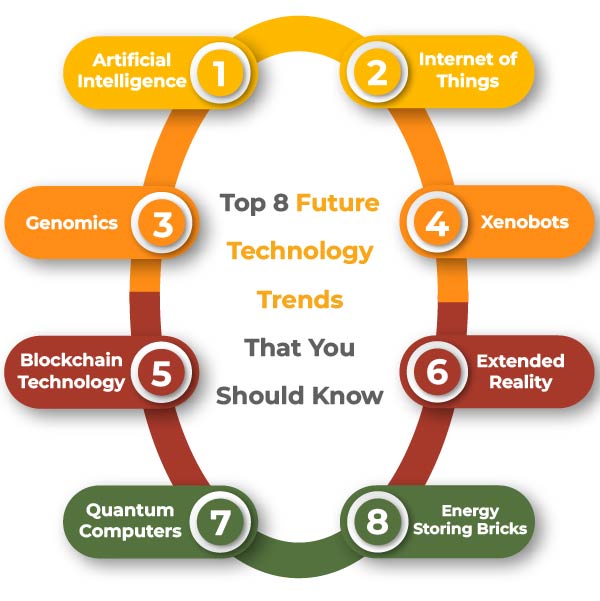

The year 2025 is rapidly approaching, and with it, a wave of transformative technological advancements. Among these, 3D trends are poised to play a pivotal role in shaping the future across diverse industries, from entertainment and healthcare to manufacturing and education.

This article will delve into the key 3D trends expected to dominate 2025, exploring their potential impact and outlining the benefits they offer. We will also examine related searches, address frequently asked questions, provide insightful tips, and conclude with a comprehensive overview of the broader implications of these trends.

1. Advancements in 3D Printing Technology

A. Material Innovation: 3D printing, also known as additive manufacturing, is rapidly evolving beyond its initial focus on plastics. Researchers are making significant strides in developing new materials, including:

- Metals: 3D printing with metal alloys is gaining traction in aerospace, automotive, and medical device industries, enabling the creation of complex, lightweight, and highly durable components.

- Ceramics: 3D printing of ceramics is opening up new possibilities in areas like dental implants, prosthetics, and high-temperature applications.

- Composites: Combining different materials like polymers and fibers through 3D printing allows for the creation of customized composites with tailored properties, ideal for aerospace, automotive, and construction industries.

B. Increased Resolution and Accuracy: 3D printing technology is constantly improving in terms of resolution and accuracy. This translates to:

- Finer Detailing: The ability to create objects with more intricate details and finer features, opening up new possibilities in jewelry design, medical implants, and even microelectronics.

- Enhanced Precision: Increased accuracy ensures that 3D-printed components meet stringent tolerances, making them suitable for applications requiring high precision, such as aerospace and medical devices.

C. Scalability and Automation: 3D printing is moving beyond the realm of small-scale prototypes and entering the realm of mass production. This is driven by:

- Larger Printing Volumes: The development of larger 3D printing machines enables the production of larger objects and components, paving the way for industrial-scale applications.

- Automated Production Lines: Integrating 3D printing into automated production lines allows for continuous and efficient manufacturing, further increasing the scalability of the technology.

2. Immersive Experiences with 3D Virtual and Augmented Reality

A. Virtual Reality (VR) in Entertainment and Training: VR technology is rapidly evolving, offering increasingly immersive and realistic experiences.

- Gaming: VR gaming is experiencing explosive growth, with developers creating immersive experiences that blur the lines between reality and virtual worlds.

- Training and Simulation: VR is proving invaluable for training in various industries, from healthcare and aviation to manufacturing and military operations. It allows users to practice complex procedures and skills in a safe and controlled environment.

B. Augmented Reality (AR) in Retail and Education: AR technology overlays digital information onto the real world, enriching our perception and interaction with the environment.

- Retail: AR applications allow customers to visualize products in their own space, enhancing the shopping experience and driving sales.

- Education: AR can bring learning materials to life, making education more engaging and interactive. Students can explore historical sites, dissect virtual organs, or even interact with virtual tutors.

3. 3D Scanning and its Applications

A. Reverse Engineering and Design Optimization: 3D scanning captures the precise shape and dimensions of real-world objects, creating digital models that can be used for:

- Reverse Engineering: Analyzing existing products to understand their design and functionality, enabling improvements or the creation of new products based on existing ones.

- Design Optimization: Using 3D scans to create accurate digital models allows designers to optimize product designs, reducing material waste and improving performance.

B. Medical Applications: 3D scanning is transforming healthcare by enabling:

- Personalized Medicine: Creating custom-fit medical devices, prosthetics, and implants based on individual patient scans.

- Surgical Planning: Using 3D scans to create detailed models of patients’ anatomy, allowing surgeons to plan complex surgeries more effectively.

C. Heritage Preservation and Archaeology: 3D scanning is playing a vital role in preserving cultural heritage by:

- Documenting Artifacts: Creating digital records of ancient artifacts, sculptures, and historical sites, preserving them for future generations.

- Virtual Reconstruction: Using 3D scans to reconstruct damaged or lost artifacts, bringing history back to life.

4. The Rise of 3D Modeling and Animation

A. Enhanced Realism and Detail: 3D modeling software is continuously evolving, offering more realistic and detailed models. This is achieved through:

- Advanced Rendering Techniques: New rendering techniques create more realistic lighting, shadows, and textures, enhancing the visual fidelity of 3D models.

- Improved Modeling Tools: Advanced tools allow for more precise and detailed modeling, enabling the creation of complex and lifelike objects.

B. Applications in Film, Television, and Gaming: 3D modeling and animation are essential for creating immersive and engaging content in:

- Film and Television: Creating realistic special effects, characters, and environments for movies and TV shows.

- Gaming: Developing stunning graphics and interactive environments for video games.

C. Industrial Design and Prototyping: 3D modeling is used in various industrial applications, including:

- Product Design: Creating 3D models of products before they are manufactured, allowing for early visualization and design iterations.

- Prototyping: Generating physical prototypes from 3D models, enabling faster and more efficient development cycles.

5. The Expanding Role of 3D in Healthcare

A. Personalized Treatment Plans: 3D technology is revolutionizing healthcare by enabling:

- 3D-Printed Medical Devices: Creating custom-fit implants, prosthetics, and surgical guides, tailored to individual patients.

- Virtual Reality Therapy: Using VR to treat phobias, anxiety disorders, and even chronic pain, offering immersive and engaging therapies.

B. Advanced Diagnostic Tools: 3D imaging techniques are providing more accurate and detailed diagnoses, leading to:

- Improved Cancer Detection: 3D imaging can detect tumors and other abnormalities earlier, allowing for more effective treatment.

- Enhanced Surgical Planning: 3D scans of patients’ anatomy allow surgeons to plan complex procedures more accurately.

C. Telemedicine and Remote Monitoring: 3D technology is facilitating remote healthcare services by:

- Virtual Consultations: Allowing patients to consult with doctors remotely, improving access to healthcare in remote areas.

- Remote Monitoring: Using 3D sensors to monitor patients’ vital signs and other health indicators remotely.

6. 3D in Architecture and Construction

A. Building Information Modeling (BIM): BIM is a process that uses 3D modeling to create digital representations of buildings, enabling:

- Improved Design Collaboration: Allowing architects, engineers, and contractors to collaborate effectively on projects.

- Reduced Construction Costs: Optimizing building designs and minimizing waste during construction.

B. 3D Printing of Buildings: 3D printing is emerging as a revolutionary technology in the construction industry, offering:

- Faster Construction Times: Printing buildings on-site reduces construction time and labor costs.

- Sustainable Construction: Reducing waste and minimizing environmental impact.

C. Virtual Reality for Site Visualization: VR technology allows architects and clients to experience building designs in a realistic virtual environment, enabling:

- Improved Design Feedback: Getting early feedback on design concepts before construction begins.

- Enhanced Client Engagement: Allowing clients to visualize and understand their projects more effectively.

7. The Impact of 3D on Education

A. Engaging and Interactive Learning: 3D technology is transforming education by providing:

- Immersive Learning Environments: Creating virtual field trips, interactive simulations, and 3D models that enhance learning.

- Personalized Learning Experiences: Tailoring educational content to individual students’ needs and learning styles.

B. Developing STEM Skills: 3D technology is promoting STEM education by providing students with:

- Hands-on Learning Experiences: Using 3D printing and modeling to design and create physical objects.

- Problem-Solving and Critical Thinking Skills: Developing skills in design, engineering, and technology.

C. Accessibility and Inclusivity: 3D technology is making education more accessible to diverse learners by:

- Creating Accessible Learning Materials: Developing 3D models and animations that are accessible to students with disabilities.

- Providing Remote Learning Opportunities: Facilitating virtual classrooms and online learning experiences.

8. 3D Technology and the Future of Manufacturing

A. Mass Customization and Personalized Products: 3D printing enables the production of customized products, offering:

- Unique Products: Creating products tailored to individual customer needs and preferences.

- Reduced Inventory: Producing products on demand, eliminating the need for large inventories.

B. On-Demand Manufacturing and Decentralized Production: 3D printing allows for localized production, leading to:

- Shorter Lead Times: Reducing the time it takes to manufacture products, improving responsiveness to market demands.

- Reduced Shipping Costs: Manufacturing products closer to customers, reducing transportation costs and environmental impact.

C. Sustainable Manufacturing Practices: 3D printing promotes sustainable manufacturing by:

- Reducing Waste: Creating products with minimal waste, using only the necessary materials.

- Using Recycled Materials: Printing with recycled materials, promoting a circular economy.

Related Searches

- 3D Printing Trends 2025: Focuses on advancements in 3D printing technology, materials, and applications.

- Future of 3D Technology: Explores the long-term impact of 3D technology on various industries and society as a whole.

- 3D Modeling Software 2025: Discusses the latest advancements in 3D modeling software, including new features and functionalities.

- 3D Animation Trends 2025: Examines emerging trends in 3D animation, such as real-time rendering and motion capture technology.

- Virtual Reality 2025: Explores the future of VR technology, including its applications in entertainment, education, and healthcare.

- Augmented Reality 2025: Discusses the growth of AR technology, its potential in retail, education, and manufacturing.

- 3D Scanning Applications: Covers the diverse applications of 3D scanning, including reverse engineering, medical imaging, and heritage preservation.

- Impact of 3D Technology on the Economy: Analyzes the economic implications of 3D technology, including its potential to create new jobs and industries.

FAQs about 3D Trends 2025

1. What are the biggest challenges facing the adoption of 3D technology?

- Cost: 3D printing and other 3D technologies can be expensive, particularly for large-scale applications.

- Skill Gap: There is a shortage of skilled workers with expertise in 3D technology.

- Regulation: The lack of clear regulations for 3D printing and other emerging technologies can hinder adoption.

- Material Development: The development of new materials suitable for 3D printing is an ongoing challenge.

2. How will 3D technology impact the job market?

- Job Displacement: Some jobs may be automated or made redundant due to the adoption of 3D technology.

- New Job Creation: The growth of 3D technology will also create new jobs in areas like 3D printing, design, and engineering.

- Reskilling and Upskilling: Workers will need to adapt and acquire new skills to remain competitive in the evolving job market.

3. What are the ethical considerations surrounding 3D technology?

- Intellectual Property: The ease of replicating designs using 3D printing raises concerns about intellectual property rights.

- Privacy: The use of 3D scanning and facial recognition technology raises privacy concerns.

- Security: The potential for 3D printing to be used to create counterfeit products or weapons poses security risks.

4. What are the environmental implications of 3D technology?

- Reduced Waste: 3D printing can reduce waste by using only the necessary materials, promoting a circular economy.

- Energy Consumption: The energy required to operate 3D printing equipment can be significant, requiring sustainable energy sources.

- Material Sourcing: The sourcing of materials for 3D printing should be environmentally responsible.

Tips for Embracing 3D Trends in 2025

- Invest in Training and Education: Develop skills in 3D technologies, such as 3D modeling, animation, and printing.

- Explore New Applications: Identify opportunities to use 3D technology in your industry or business.

- Stay Informed about Advancements: Keep abreast of the latest developments in 3D technology and its applications.

- Collaborate with Experts: Partner with 3D technology companies and experts to leverage their knowledge and expertise.

- Embrace Innovation: Be open to new ideas and approaches, and experiment with 3D technologies to discover their potential.

Conclusion

3D trends are poised to transform industries and reshape our world in 2025 and beyond. From advancements in 3D printing to the growing adoption of virtual and augmented reality, these technologies are offering unprecedented opportunities for innovation, efficiency, and progress. Embracing 3D trends will require a willingness to adapt, invest in new skills, and explore the limitless potential of this rapidly evolving field. By understanding the implications of these trends and embracing their transformative power, we can unlock a future where technology empowers us to create a more sustainable, efficient, and enriching world.

Closure

Thus, we hope this article has provided valuable insights into 3D Trends 2025: Shaping the Future of Technology and Beyond. We thank you for taking the time to read this article. See you in our next article!